Efficient water sourcing

Whether water is sourced from lakes, rivers, rainwater or municipal supply, Grundfos' reliable and intelligent pumps and components harvest, treat and boost the water onwards.

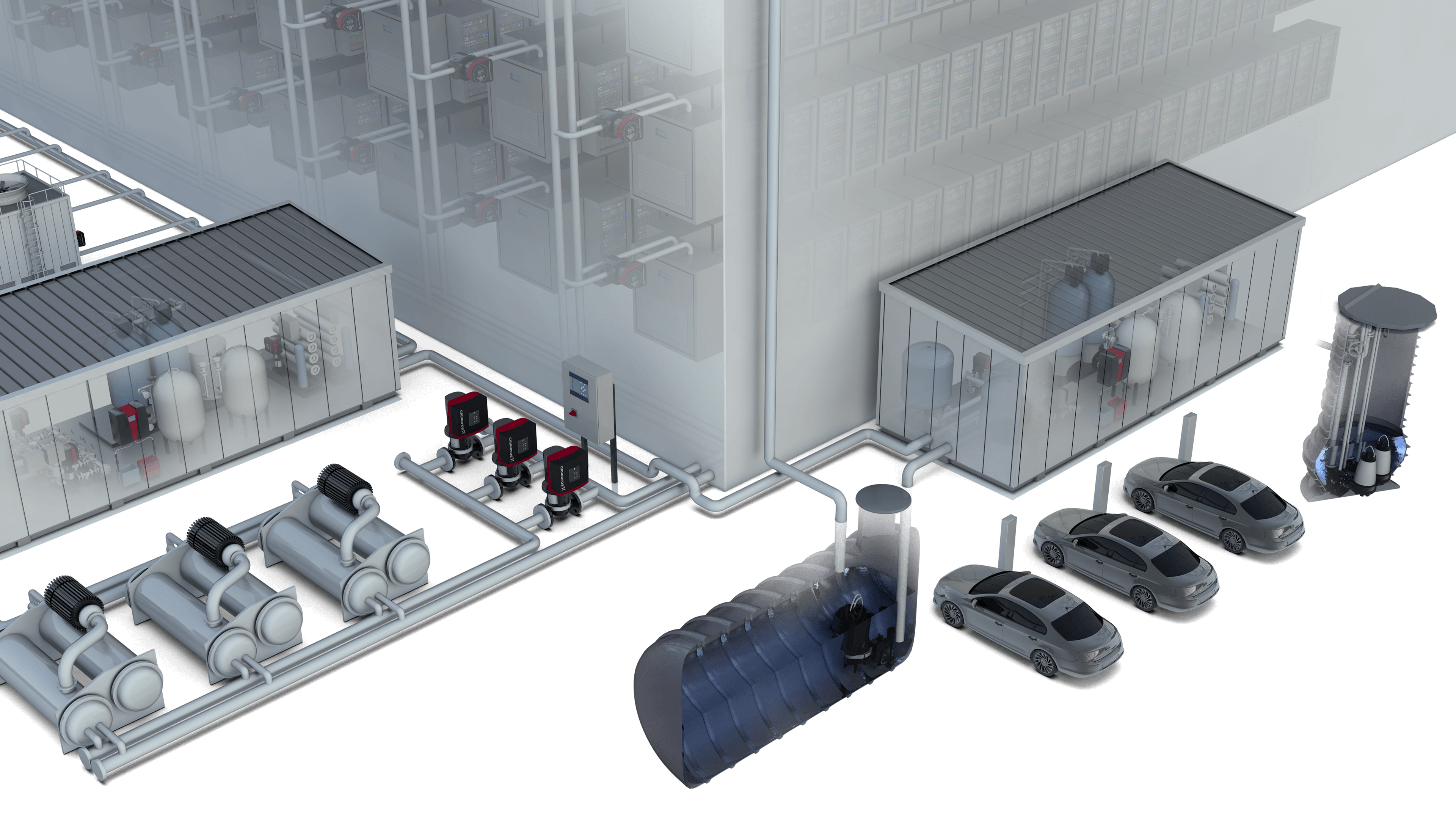

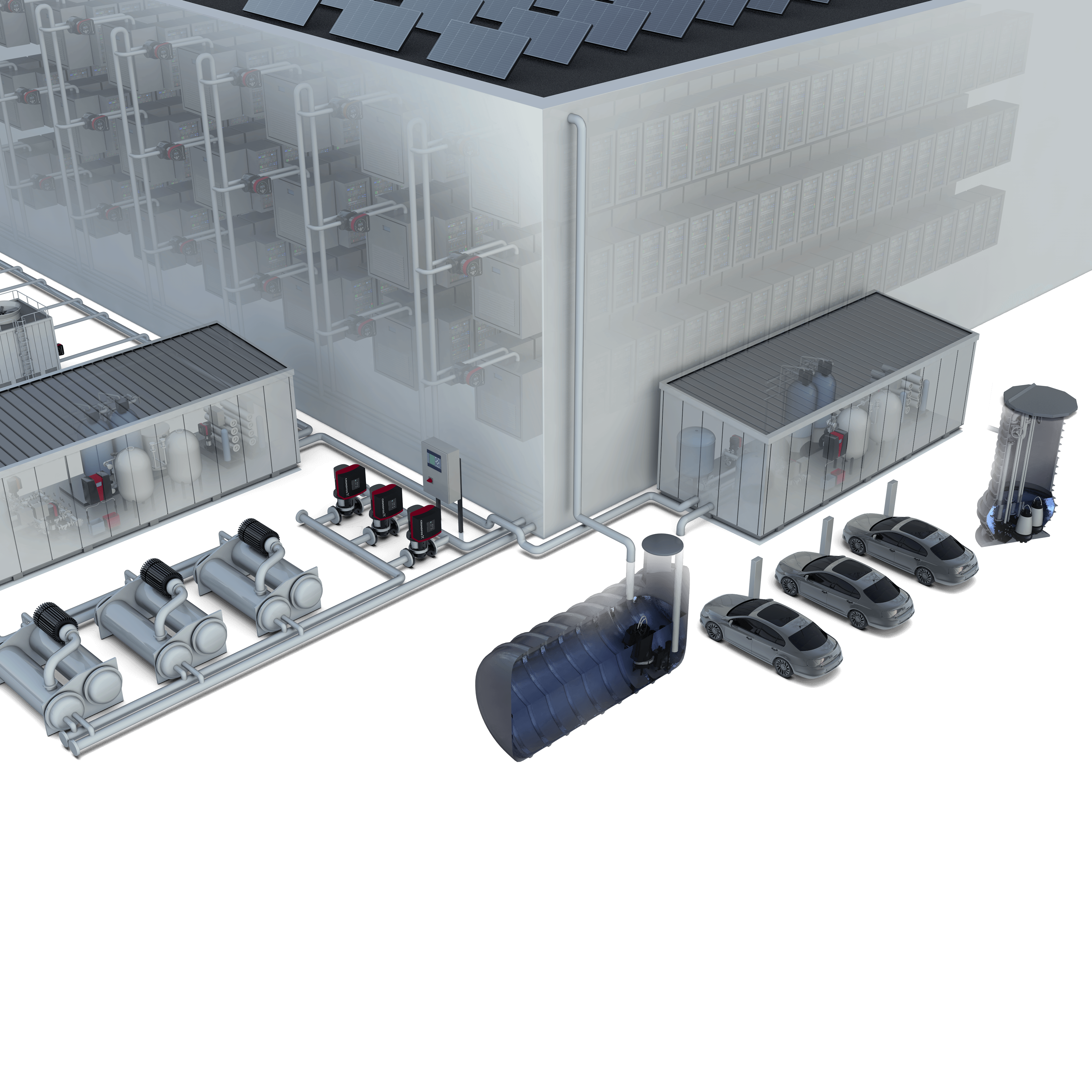

Rainwater harvesting

Water is a finite resource and with a focus on WUE in the data center industry it makes sense to collect and treat rainwater for use in the data center's process systems, such as cooling towers and evaporative coolers.

Grundfos rainwater harvesting systems collect and treat rainwater, which is stored in rainwater tank systems around the site and pumped into the data center's water supply system using pressure boosters.

Surface water intake

If your data center is located close to natural water sources, we offer tailored pump solutions for varied demands of surface water intake at the lake shore or riverbank, including efficient and reliable axial flow propellor pumps, mixed flow pumps and submersible pumps.

Discover more:

Ground water intake | GrundfosSurface water intake | GrundfosEfficient water distribution

Optimising your energy savings lies in the use of highly advanced controls combined with highly efficient pumps. The Grundfos MPC systems use the CU 352 control unit to efficiently control and monitor your pump systems.

Specially designed for the control of parallel connected pumps, the Grundfos MPC is easy to operate and monitor, and offers advanced functionality and redundancy to control and monitor your data center pump systems.

The Grundfos MPC offers perfect control over your pumps:

- Constant pressure

- Easy to operate

- Monitoring

- Communication

- Energy Reduction

- Optimised application functions

Discover more:

Water distribution | GrundfosCommercial water pressure boosting | GrundfosHydro MPC | GrundfosSuperior water treatment

Digital Dosing™ solutions ensure precise, chemical-saving dosing of pH regulation chemicals as well as flocculation and anti-scaling / anti-fouling aids.

Oxiperm® represents a highly efficient, compact chlorine dioxide preparation solution and is used for disinfection applications in cooling systems, warm water cycles and combating legionella.

Hydro Protect is an ingenious Plug & Play solution designed by Grundfos. It combines the benefits of a disinfection and booster system. An Oxiperm Pro chlorine dioxide generator and a speed-controlled booster station are installed on a common framework. A measuring and control unit completes the system.

Discover more:

Commercial water disinfection | GrundfosEasier system integration

Reduced time, low-cost integration of Grundfos solutions into BMS & SCADA systems, with fewer field cables and easier data point mapping over a wide range of BUS protocols.

For complete control of pump systems, the Grundfos fieldbus concept is the ideal solution. The innovative Communication Interface Module (CIM) and the Communication Interface Unit (CIU) enable data communication via open and interoperable networks. All the main communication protocols are catered for.

- Easier BMS integration and commissioning

- Reduced downtime, due to monitoring and control functionality

- Potential energy and water savings

- Remote, real time monitoring

Minimal downtime and waste water risk

Grundfos offers a full range of functional modular pumping stations - complete with all necessary piping, valves and level controls etc. It is a modular concept with increased sump volume.

The pump pit, pumps and controls can be combined to suit specific requirements for each individual application, reducing the installation complexity.

- Modular flexibility enables many adaptations to individual specifications. Inlet pipes are installed on-site to fit actual needs

- The unique design and corrosion-free materials make the pumping stations very service-friendly and easy to maintain

- The pumping stations are pre-mounted with all necessary pipes and valves, ready for installation

- The special design of the moulded pit makes it dimensionally stable and extremely sturdy. The shoulder of the pit prevents upthrust

- The design of the sump limits sludge and odour problems

Discover more:

Commercial wastewater | GrundfosReduce chemical & filter costs by up to 70%

Monitoring of typical water quality parameters as well as precise control of chemicals and disinfection or pH adjustment is essential for water treatment processes.

Grundfos offers the DIT hand-held photometer, and the online measuring and control system DID for full integration with digital communication and data logging.

Chemical management app

The chemical management app makes chemical management and regulatory compliance reporting easy with cloud-based and automated functions.

Complete dosing skids tailored to your application

The complete chemical feed systems are designed to make dosing technology available as a complete package with all necessary pipework, valves and dosing pumps. With more than 30 years' experience designing and fabricating chemical dosing skids, we can deliver standardised packaged systems or build custom systems to your specifications.

Discover more:

Commercial water disinfectionReduce CAPEX and OPEX with district energy reheating

Data center heat reuse in heat networks is beneficial for both data center and heat network operators. Data center operators can benefit from:

- Savings in operational costs of cooling systems. For the studied use case of 10 MW scale data center, the savings can exceed €1M annually, depending on the geographical location

- Further savings in both OPEX and CAPEX due to the change of the cooling system design resulting in less equipment installed on site, as the baseload cooling function is provided by the heat upgrading plan.

Grundfos can help optimise your district heating to run with lower temperatures:

- Reliable and highly efficient pumps for all application in production, distribution and consumption in the district heating network.

- Solutions that improve the efficiency of your system; e.g. temperature zoning, pressure boosting and pressure optimisation.

- Services to ensure optimal operation and performance of your system; e.g. commissioning, energy checks, pump audits and service contracts.

- Consultancy on how to design the distribution system and utilise the intelligence built into our products and systems, helping you save money from the very first day.