Reduce pressure, energy and CAPEX with Distributed Pumping

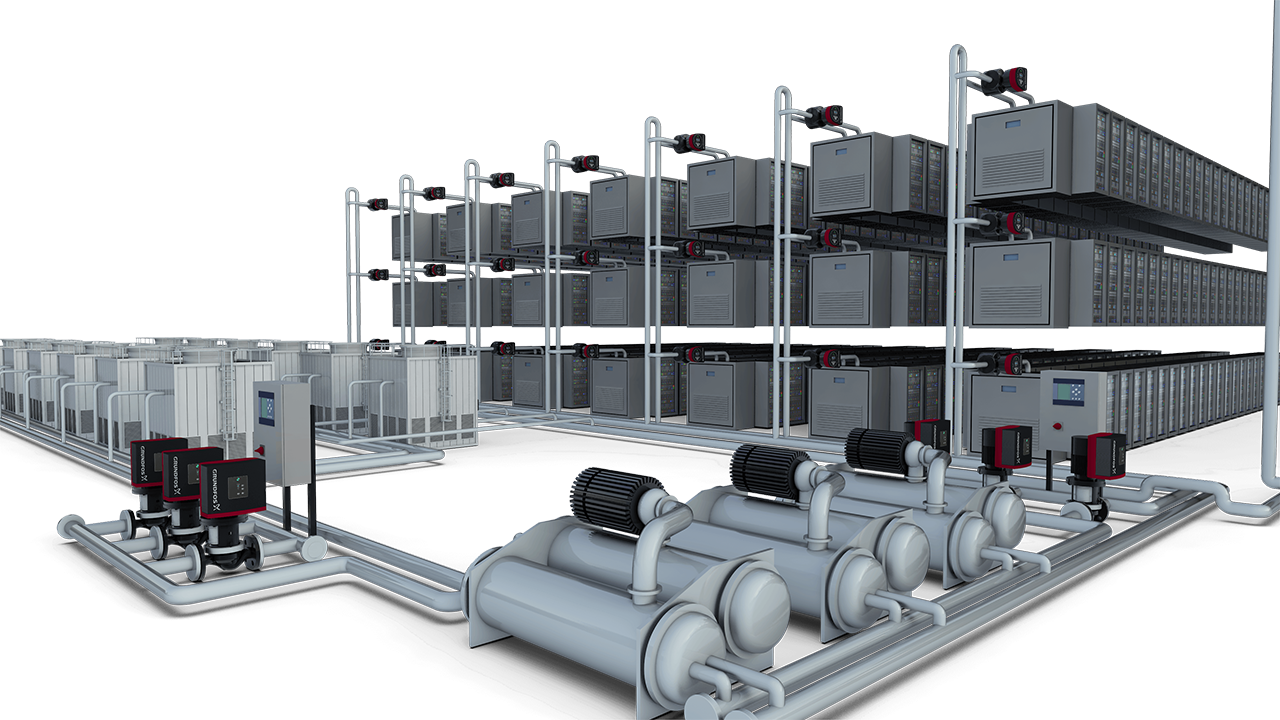

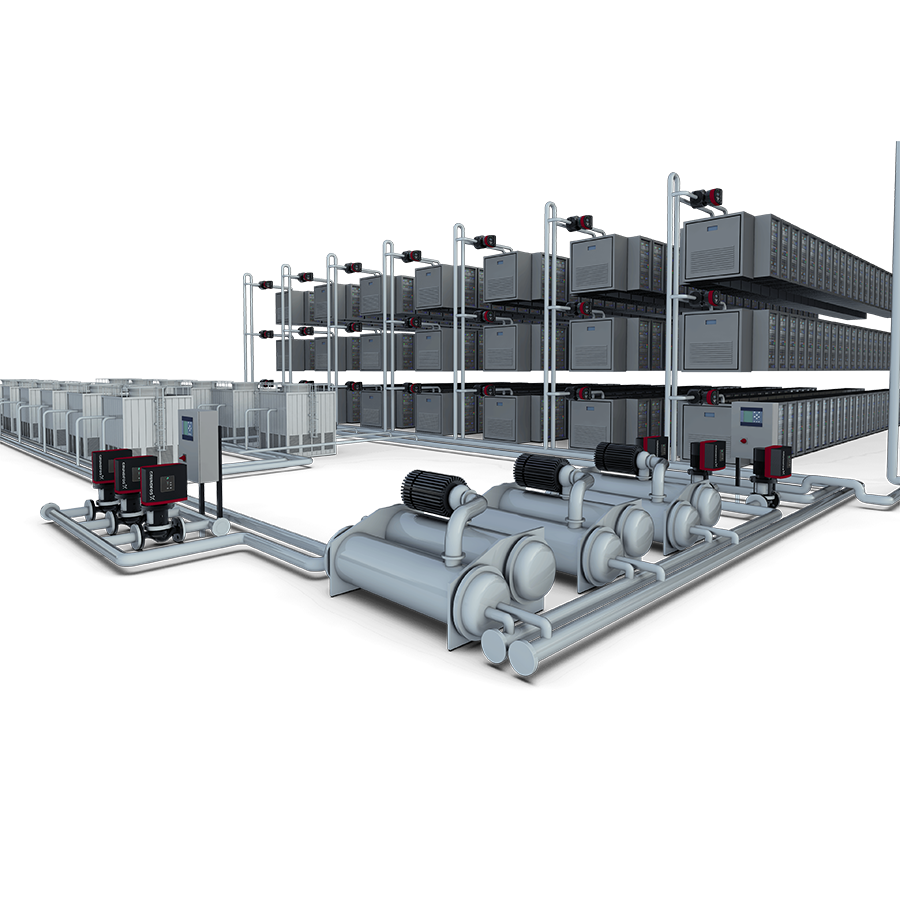

Typical chilled water hydronic systems use pumps to circulate the water through the network and control the flow with a series of balancing and control valves.

The most common arrangements are variable primary, or constant flow primary with variable flow secondary circuits, with balancing and control valves controlling the flow to the zones or CRAW units.

With Grundfos Distributed Pumping the control valves are replaced with intelligent circulation pumps. By removing the valves, we reduce the resistance in the system using the pumps to deliver the required water quantity at the required pressure.

Distributed pumping is more than replacing valves with pumps - it's a new method of efficiently distributing flow through a network, reducing energy consumption, simplifying system balancing and improving delta T.

Discover more:

Distributed pumpingIntelligent pump control

Grundfos intelligent pumps and controls deliver the optimal combination of pumps, drives and auxiliary components for the specific application, incorporating special features and functions and building on application knowledge and experience.

Grundfos solutions make integration of pumps, drives, measurement, controls and communication easy, saving you valuable engineering, installation and commissioning time.

- Optimal operation with multiple control modes.

- Intelligent pump operation increase reliability and prevent system stress.

- Lower energy consumption and total system cost.

Discover more:

Commercial air conditioningReduce downtime and service costs

Grundfos Machine Health is a predictive maintenance solution that provides real-time actionable insights into the health of your rotating equipment. Data is collected through our wireless sensors and securely stored in our user-friendly cloud-based platform, enabling remote visibility and reliability insights at all times.

With Grundfos Machine Health, we help you manage your downtime, reduce maintenance costs, and ultimately enable a journey towards a new state of machine reliability.

- Prioritise, predict and plan maintenance, eliminating unexpected downtime

- Optimise maintenance practices with a turnkey solution backed by 24/7 Grundfos experts

- Get real time prescriptive outcomes

Discover more:

Grundfos Machine HealthLower installation & commissioning costs with modular builds

Did you know:

- 60% of new construction projects experience time overrun more than 10%?

- 76% of new projects overrun budget by more than 10%?

- 75% of onsite labour can be reduced by using prefabricated systems?

Grundfos supply a full range of modular systems, designed, engineered and manufactured in a safe, controlled factory environment ensuring your data center project is delivered on time, within budget and safely.

From standard modular systems (Delta Range) to bespoke packaged plantrooms, Grundfos can deliver modular cooling, distribution and water treatment packages for your data center projects.

Discover more:

Modular system - Grundfos Delta range | GrundfosMaintaining uptime

Energy efficiency, resilience and security are key considerations when designing data centers.

Grundfos control solutions provide various levels of redundancy for pump systems including Tier III & IV requirements.

Discover more:

Hydro MPC | GrundfosUp to 20% less energy and water use for cooling towers

Improving the pump controls in cooling systems offers significant operating cost savings, up to 70% less energy consumption, prolonged service intervals and reduced risk of downtime.

Built-in functionalities in our variable speed solutions (MGE/CUE) simplify the system and reduce man hours for design, commissioning and setup:

- Risk free, easy commissioning, pre-selected components

- Commissioning of pumps, drives & motors made simpler and easy

- Commissioning wizard: enables pre-configured settings

Intelligent pumps adjust the speed and running of the pump according to the system’s needs, utilising integrated functionality in one solution.

Discover more:

Commercial air conditioning | GrundfosLower energy, water use and OPEX with liquid cooling

With the increase in IT chip densities and a focus on energy efficiency, liquid cooling is becoming a more common method of IT cooling in data centers.

Whether it's direct to chip or immersive liquid cooling, or whether the media is water or dielectric liquids, Grundfos has a range of pumps and sensors with material compatibility for your chosen liquids.

Discover more:

Commercial air conditioning | GrundfosRemote communication

For complete control of pump systems, the Grundfos fieldbus concept is the ideal solution. The innovative Communication Interface Module (CIM) and the Communication Interface Unit (CIU) enable data communication via open and interoperable networks. All the main communication protocols are catered for.

- Easier BMS integration and commissioning

- Reduced downtime, due to monitoring and control functionality

- Potential energy and water savings

- Remote, real time monitoring