Trouble-free operation

Reduction of sedimentation

See how Grundfos Dedicated Controls can reduce pit sedimentation through a range of automatic operations to ensure trouble-free operation.

Time-saving troubleshooting

Find out how the controller can save you time when troubleshooting with built-in functionalities.

Smart data

See how our controller utilises valuable smart data to ease operations and save time, ensuring trouble-free operation.

Odour control

Read how the controller enables preventive odour removal and H2S abatement in pipes and pits to ensure trouble-free operation.

User friendliness

Simple user-interface

See how Grundfos Dedicated Controls can easily be set up to your specific system needs in normal operations.

Easy SCADA integration

Learn how easy it is to configure or connect the wastewater controller to your SCADA system.

Legal report

Report overflow

See how the controller makes it easy to meet legal reporting demands and handle overflow alarms.

Lower costs

Reduced operation costs

See how Grundfos Dedicated Controls can reduce costs with optimal operation points, alarm set up and more.

Reduced investment

Learn how Grundfos Dedicated Controls can reduce total costs by generating a lot of value that would normally come from a substantial investment.

Customise

Design your system

See how Grundfos Dedicated Controls supports several design possibilities and features like run ventilation to fit into your operational system.

Reduction of sedimentation

See how Grundfos Dedicated Controls can reduce pit sedimentation through a range of automatic operations to ensure trouble-free operation.

1: Start levels

Our dedicated wastewater controller can automatically variate start levels in pits for pumps 1-6 to reduce grease and other build-up inside pumping stations, and secure accurate level measurement.

2: Automatic pump protection (anti seizing)

The controller can automatically operate pumps for a few seconds to avoid the build-up of limestone and other deposits in the pit during low-flow periods and limit the risk of pump clogging.

3: Automatic foam removal

Foam on the water surface can create inaccurate level sensing. By occasionally pumping the water level all the way down close to the pump inlet, the controller can remove the build-up of foam in the pit and prevent foam accumulating on pit walls.

4: Longer service intervals

Our controller can automatically operate variable speed pumps at full speed to protect upstream pipes against sedimentation and ensure longer service intervals.

5: Preventive maintenance

To support preventive maintenance, the controller can empty pumping stations on a daily basis in periods with little or no flow to prevent odour and sedimentation build-up.

Time-saving troubleshooting

Find out how the controller can save you time when troubleshooting with built-in functionalities.

Pump protection

Our dedicated wastewater controller allows you to select different parameters to indicate potential blocking. When these parameters are triggered, the pump stops and reverses to clean the impeller.

Pump alternation

To ensure equal wear and tear on each of the different pumps in the pit, the controller can alternate pump operation individually or in groups. This parameter allows you to service the pumps at the same time for efficient pump maintenance and service crew dispatch. Further pumps can be grouped to ensure best energy usage, using smaller pumps for normal inflow and bigger pumps for larger inflow.

Reducing alarm severity

Our controller can tie your alarms to levels in the pits which fit your conditions. This parameter will help you to quickly react to the right events.

Easy power monitoring

With the controller, you can easily add motor protection, a soft starter or a frequency converter, enabling efficient pump operation, effective alarms and trouble-free operation.

Smart data

See how our controller utilises valuable smart data to ease operations and save time, ensuring trouble-free operation.

Data logging

The controller allows you to log up to 30 different analogue values without you having to program these yourself. This data is accessible from any remote SCADA system or BMS, and the controller supports all market relevant data protocols. Just change the setting to get your smart data.

Integrate sensors

The controller is pre-programmed to add any kind of sensor. All sensor inputs can be changed to fit different sensor outputs, currents and voltages, and can be read directly on the display for any fault detection. Just change the setting to get the right smart sensor data integrated into your SCADA system.

Reduce alarms

With Grundfos Dedicated Controls, you can easily set warning limits, set up alarms, and enable/disable alarms or warnings. You can also combine alarms to optimise service events or callouts with combi-alarms to save time and let the controller react to the alarms.

Odour control

Read how the controller enables preventive odour removal and H2S abatement in pipes and pits to ensure trouble-free operation.

Preventive odour removal

With the controller’s programmed routine, it can automatically empty the pit during periods of low flow to prevent the build-up of odour in the pit.

Automatic H2S abatement

If you experience H2S generation in your pipes and pits, you can connect a sensor, our cloud solution, and a dosing pump to the controller to abate H2S levels in your sewers.

Simple user-interface

See how Grundfos Dedicated Controls can easily be set up to your specific system needs in normal operations.

Pre-programmed actions

The controller is designed to make it easy for you to operate and customise tasks to your needs. It’s built for normal wastewater operations, which means some specific actions for wastewater are pre-programmed.

Adding sensors

Part of normal wastewater operations is adding sensors. The controller’s menu is made to fit these different signals while you can program reactions to suit your operational needs.

Easy configuration wizard

To automatically integrate our controller into your operations, it has a pre-defined wizard with 20 steps. All advanced features can be activated later via the main menu.

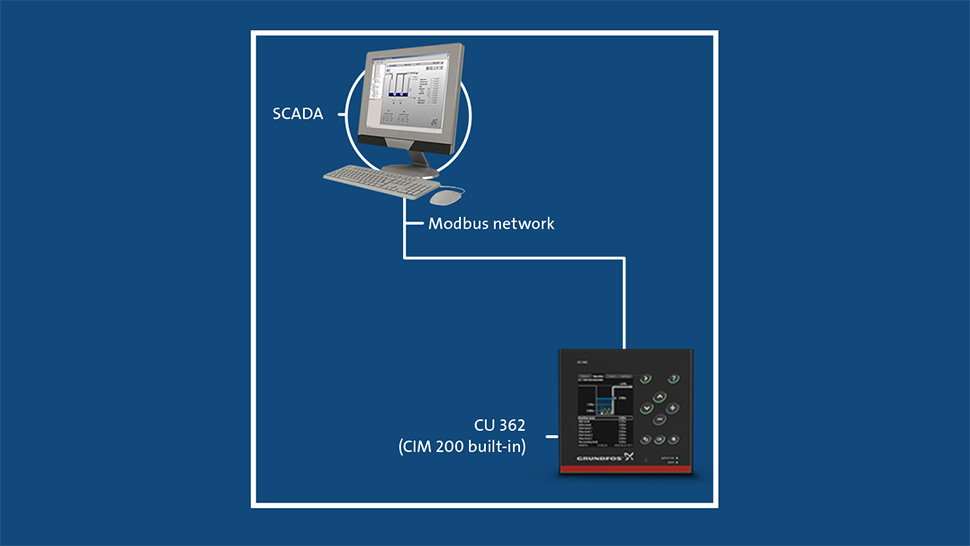

Easy SCADA integration

Learn how easy it is to configure or connect the wastewater controller to your SCADA system.

Pre-defined standard protocols

Built into the controller are pre-defined data communication packages that support most industry standard protocols for SCADA systems. This makes data integration from controller to SCADA as easy as possible. Simple data integration makes it easy to integrate and schedule SMS alarms with your SCADA system.

The controller also has a number of built-in communication cards, enabling it to communicate to any SCADA system in the market. These include modules to integrate and schedule SMS alarms with your SCADA, making it easier to integrate the controller into your daily work routines and systems.

Report overflow

See how the controller makes it easy to meet legal reporting demands and handle overflow alarms.

Handling overflows

In a wastewater network, overflow must be minimised as much as possible. That’s why our dedicated wastewater controller has a module allowing you to receive alarms in case of overflows.

The controller allows you to pre-define how to measure and store the number of overflows, the duration of the overflow, and the estimated out-flow of pumping stations or retention tanks.

In addition, Grundfos Dedicated Controls provides all the information you need for legal reporting to authorities, while the settings and configuration are easy to conduct.

Reduced operation costs

See how Grundfos Dedicated Controls can reduce costs with optimal operation points, alarm set up and more.

Optimal energy consumption

The controller is built to optimise the operational duty point of your pump system and minimise energy use. It automatically finds the optimal duty point in relation to the pump’s hydraulic efficiency – no matter which one is used. This means you can save energy in your pumping sequence without spending time finding the optimal operational point.

Easy set up

The controller is designed to handle up to six pumps in operation. It can also handle these pumps in different groups if they are different sizes, or you want to operate them based on a strategy or specific circumstances in your network. The settings are simple to program and set up, and pumps can easily be set to different start and stop levels.

Automatic foam removal

By occasionally pumping the water level all the way down below your normal stop level, the controller can remove the build-up of foam in the pit and prevent foam accumulating on the pit walls.

Pump protection

The controller allows you to select different parameters to indicate potential blocking. When these parameters are triggered, the pump stops and reverses to clean the impeller, saving you troubleshooting time.

Reduce alarms

With Grundfos Dedicated Controls, you can easily set warning limits, set up alarms, and enable/disable alarms or warnings. You can also combine alarms to optimise service events or callouts with combi-alarms to save time and let the controller react to the alarms.

Reduced investment

Learn how Grundfos Dedicated Controls can reduce total costs by generating a lot of value that would normally come from a substantial investment.

Advanced flow estimation

In existing pumping stations, it’s often difficult and expensive to add a flow sensor to better understand system flow. Our controller has an advanced flow estimation function, which with level and pressure sensors on the outlet pipe enables flow estimates of pumping station in-flow and out-flow. These estimates give you insights into water movement in the network, which can be used in situations with additional flow linked to rain or storm flood events, or to calibrate your hydraulic models without installing an expensive flow sensor. Our advanced flow estimation works on both fixed speed and variable speed pumps.

Add your requirements

Our wastewater controller is an advanced solution designed to make pumping wastewater quick and simple. Since the controller can’t be equipped with all variants, we’ve designed it so it’s possible to add your own requirements, which can then be monitored and controlled from your SCADA system. This includes signals like ‘run ventilation’ or ‘open door to pumping stations’. In addition, the controller comes with a full overview of pumping data display so you can see if the pumps are operating optimally to ensure equal wear and tear on pumps.

Add mixer control

A typical addition to wastewater systems is a tank mixer to help minimise sedimentation and keep water moving. The controller offers an easy way to control and manage a mixer to fit pump starts and stops, and determine how long the mixer should run. All are pre-programmed to get the solution up and running fast, and enable status and control in your SCADA system.

Design your system

See how Grundfos Dedicated Controls supports several design possibilities and features like run ventilation to fit into your operational system.

Add your requirements

Our wastewater controller is an advanced solution designed to make pumping wastewater quick and simple. Since the controller can’t be equipped with all variants, we’ve designed it so it’s possible to add your own requirements, which can then be monitored and controlled from your SCADA system. This includes signals like ‘run ventilation’ or ‘open door to pumping stations’. In addition, the controller comes with a full overview of pumping data display so you can see if the pumps are operating optimally to ensure equal wear and tear on pumps.

Add mixer control

A typical addition to wastewater systems is a tank mixer to help minimise sedimentation and keep water moving. The controller offers an easy way to control and manage a mixer to fit pump starts and stops, and determine how long the mixer should run. All are pre-programmed to get the solution up and running fast, and enable status and control in your SCADA system.